Problem solving competence

since 1946

In-house toolmaking. Optimum quality and delivery reliability.

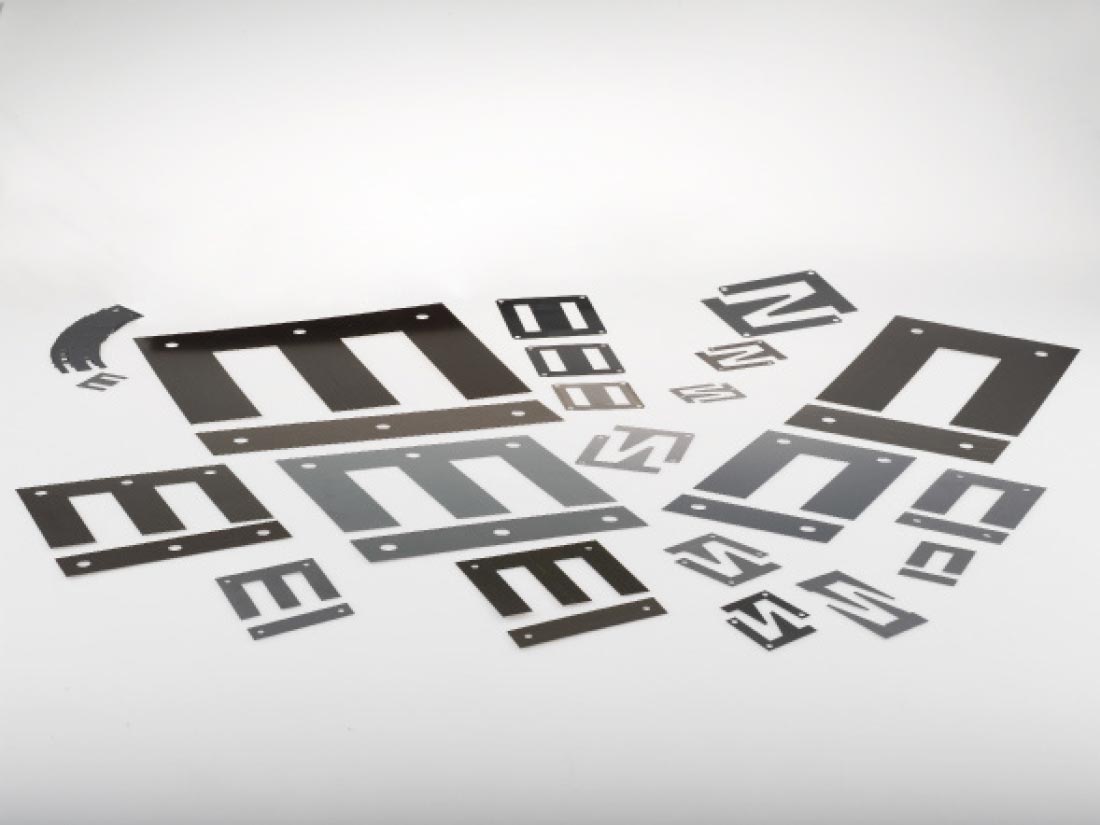

EI & WEI CORE LAMINATIONS

The patented new cut WEI was developed especially for the transformer manufacturer for the series production of welded transformers. This cut, already proven a million times over, is characterized by the following serious advantages over the conventional EI sheet, among others:

a.) The hum of a welded WEI – transformer core is no longer perceptible, even at high induction.

b.) The widespread gluing of the center tongue in welded transformers is no longer necessary due to the use of WEI – core sheets.

c.) Excellent electrical values, smaller no-load currents, smaller power loss due to the elimination of the air gap between the E + I part.

When processing for the welded transformer, it should be noted that the I – sheet with the identification (identification groove or identification stud) is applied to the E – leg. This new WEI cut is also suitable for further processing with the stacking machine. The I-sheet with the identification is turned by 180° in relation to the welded transformer, so that the identification is located on the outside of the transformer.

Ready Core Laminations

The laminations have a “latching nose”, which helps in a particularly fast and therefore commercially interesting processing. These plates are available in EI and UI versions.

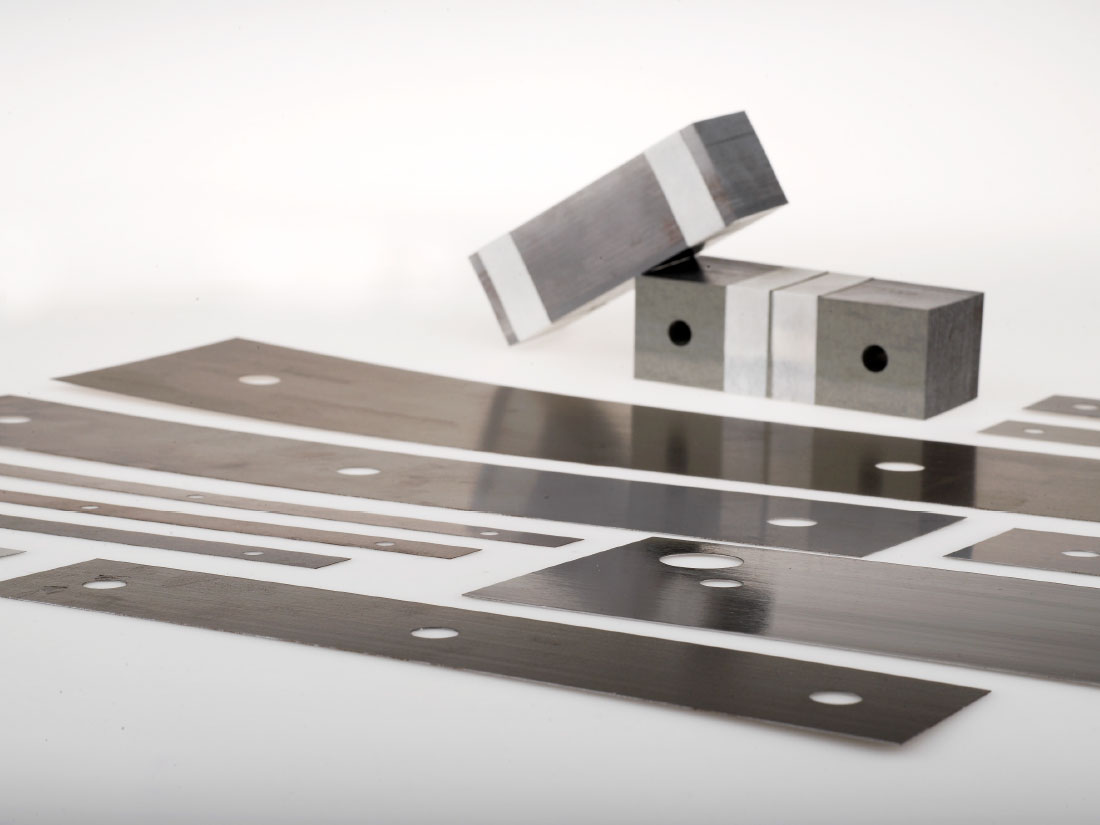

STRIP LAMINATIONS

WAASNER is able to produce strip laminations from all material qualities in variable lengths, widths, hole spacing and hole diameters.

SLITTING MATERIAL

We offer electrical steel strip made of grain-oriented and non-grain-oriented electrical steel sheet to meet specific needs.

TOROIDAL TAPE CORES

We offer toroidal tape cores in a wide range of dimensions, materials and consolidation types

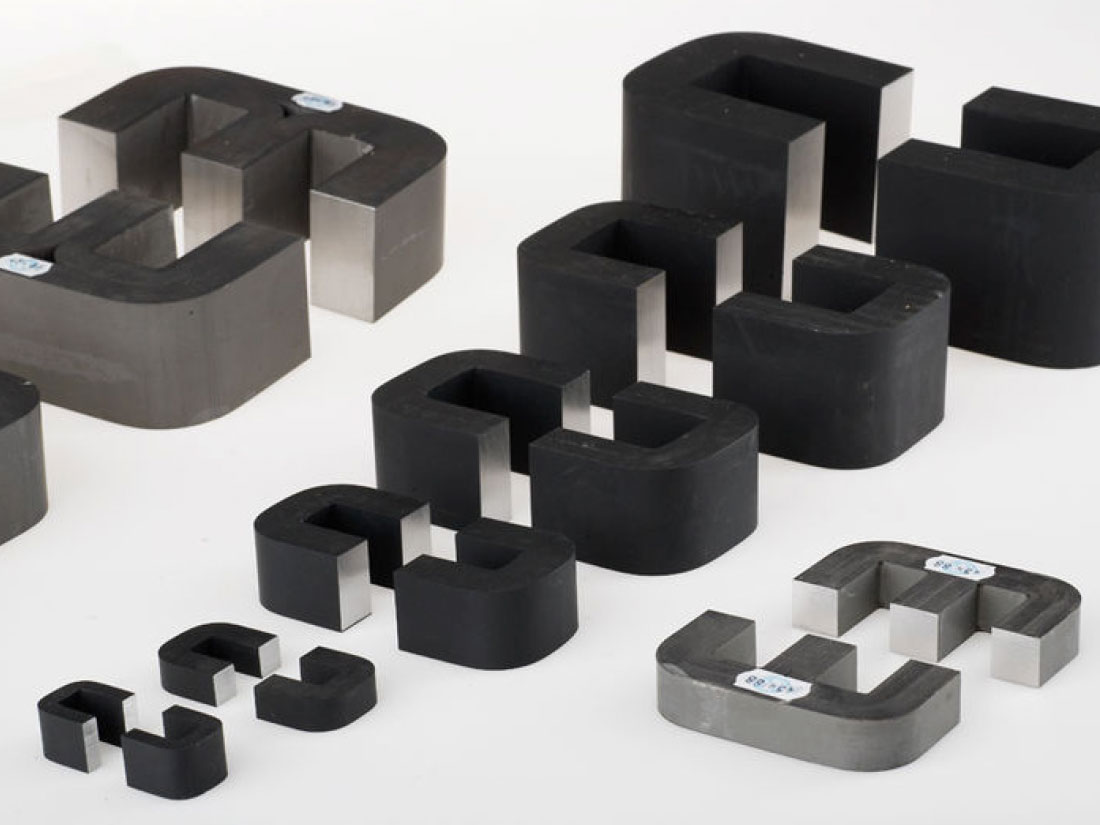

SPLIT TAPE CORES

We offer split tape cores in common DIN types and various special shapes.