Individual, customer-specific motor components.

Solutions that no one else has.

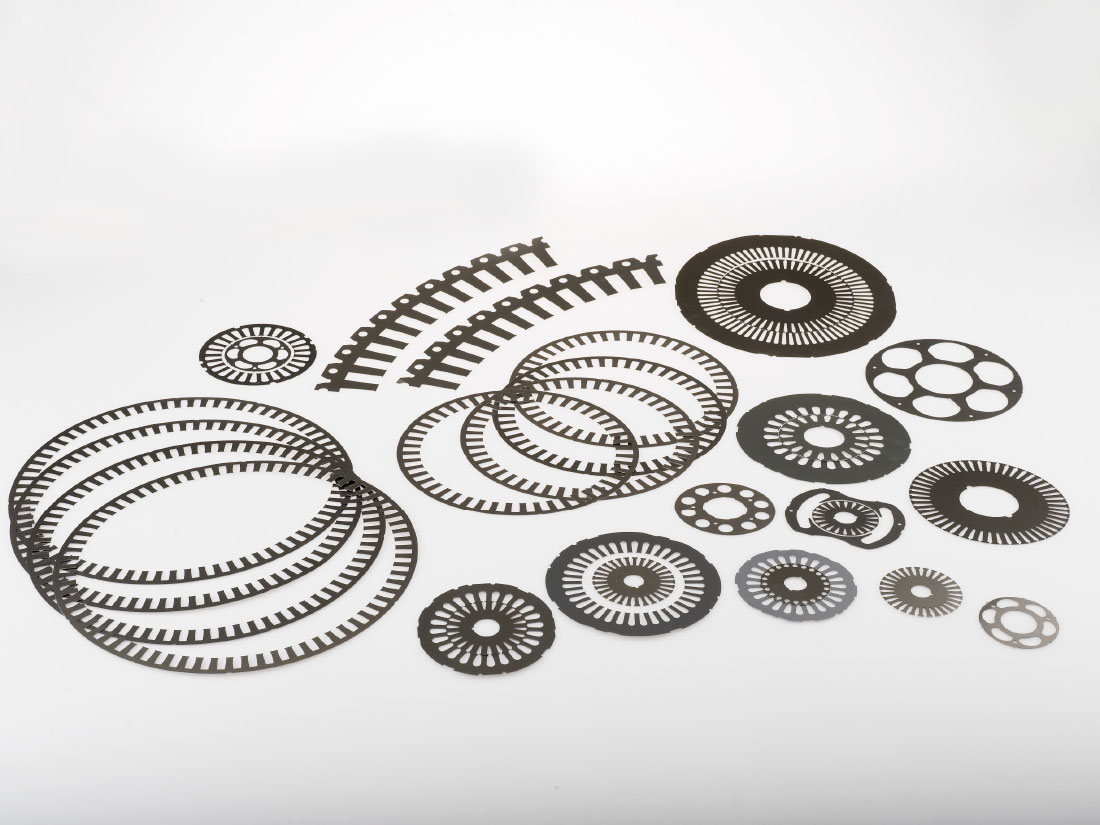

STATOR AND ROTOR LAMINATIONS – LOOSE LAMINATIONS

Stator and rotor laminations are individually designed and produced in a wide variety of shapes and sizes for a wide range of applications. They are encountered in everyday life in the form of window regulators, linear drives, torque drives, HVAC drives and actuators.

STATOR AND ROTOR STACKS – INTERLOCKED

The joining of stator and rotor laminations by interlocking is used in particular for products with high-volume production, e.g. in the automotive sector. We realize complex lamination stacks for advanced BLDC design concepts. They are subsequently found in steering and stepper motors as well as in electronic valve trains, fuel pumps, servo drives and engine cooling.